| |

|

Eratech Pte Ltd - CMM STATUS 7107 MACHINE

BROWN & SHARPE CMM STATUS 7107

Status Performance

| Model |

Strokes (mm) |

Measurement Uncertainty

by Probe Type (μm) |

Touch

Probe |

Touch

Probe |

| X |

Y |

Z |

MPEX |

MPEP (3)

|

| 7107 |

700 |

1000 |

650 |

3+L/250 |

2.8 |

Scale

Resol:

μm |

Max.3D

(v)

|

Max. 3D

(a)

|

Max.

Part

Weight

(kg) |

ASME B89 Measurement

Performance (mm) |

| All Sensors |

Touch Probe |

Volumetric(2)(4)

Accuracy |

Repeatability(5) |

| 0.15 |

520 mm/sec |

1732 mm/sec2 |

907 |

0.008 |

0.00015 |

- Volumetric measuring uncertainty along any direction in space according to ISO 10360-2. (Please refer to Brown and Sharpe document

“Understanding the ISO 10360-2 Performance Standard”).

- Volumetric uncertainty is valid for the following conditions; average room temperature for any hour 65-72 °F, superimposed air conditioning

cycle ±4.1 °F at 4 cycles /hr min,max temperature difference between any two points close to machine 1.8 °F. At installation if the environment

does not conform to the above mentioned requirements, Brown & Sharpe reserves the right to derate the machine volumetric performance

accordingly. For ASME, the methods prescribed in B89.4.1-1997, paragraph 4.2 apply. For ISO 10360-2 the second term of ‘E’ may be degraded by up to

1μm/per meter/per degree.

- Volumetric probing uncertainty according to ISO-10360-2.

- Volumetric accuracy according to ASME B89.4.1-1997, paragraph 5.5

- Repeatability according to ASME B89.4.1-1997, paragraph 5.3.

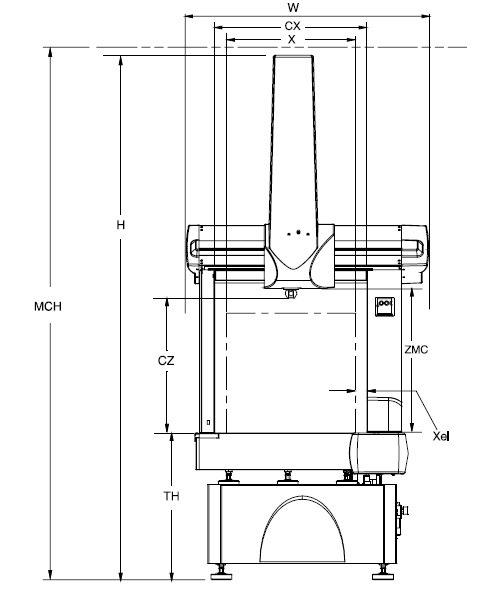

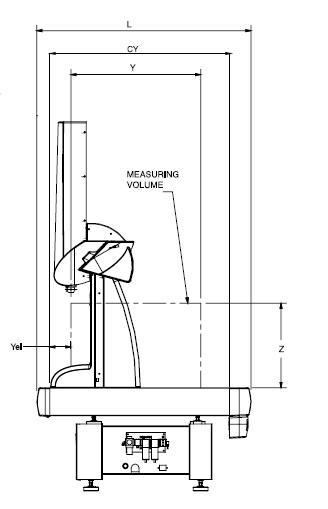

Global Dimension

| Model |

Strokes (mm) |

Overall Dimension (mm) |

TH

(MM) |

MCH

(MM) |

| X |

Y |

Z |

L |

W |

H |

| 7107 |

700 |

1000 |

650 |

1950 |

1315 |

2842 |

800 |

2870 |

Work Capacity (mm) |

Z max Clearance (mm) |

Envolope location (mm) |

Machine Weight (kg) |

| CX |

CY |

CZ |

Zmc |

Xel |

Yel |

| 825 |

2870 |

730 |

810 |

61 |

162 |

1255 |

|

|